Making the Best Threads

|

How you cut steel pipes has a great influence on the shape of a thread |

|

| |

1) Use the most appropriate cutting tool for the type of pipe used. |

.gif) Depending on your intended use, refer to the following for cutting steel pipes used for construction equipment. Depending on your intended use, refer to the following for cutting steel pipes used for construction equipment. |

| |

| |

| Type |

Blade |

Appropriate REX Products |

Steel Pipe |

Stainless

Steel Pipe |

Band saw cutting

machine |

Band saw |

Mantis 125/120A/180WS/180WA |

OK |

OK |

Circular saw

cutting machine |

Circular saw |

Carbide cutter TC-20 -150 |

OK |

|

| Pipe cutter |

Cutter wheel |

Cutter on pipe machine

(standard equipment) |

OK |

OK * |

| Table 1. Types of Cutter and their use |

* Optional cutter wheel |

|

| |

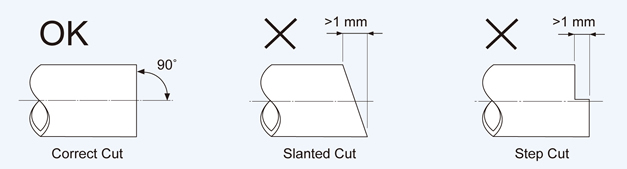

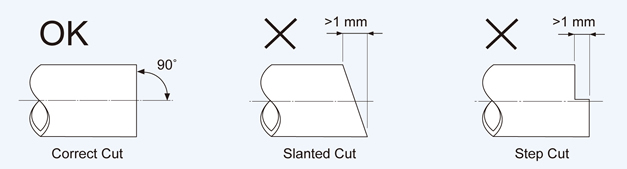

2) Cutting precision has a great influence on the shape of the thread. |

.gif) Only use pipes with a flat, right angled cut. Avoid using pipes with a slant or step of more than 1mm. (Fig. 1) Only use pipes with a flat, right angled cut. Avoid using pipes with a slant or step of more than 1mm. (Fig. 1)

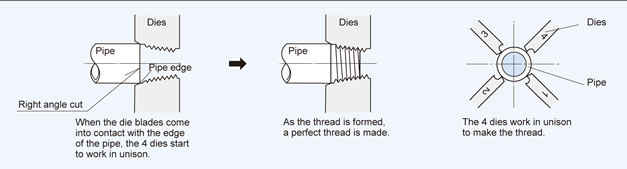

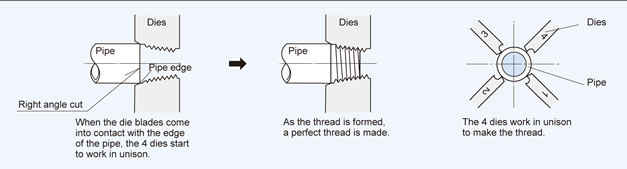

.gif) - When a thread is cut on a steel pipe that has been correctly cut at right angles, the 4 dies work in unison to cut - When a thread is cut on a steel pipe that has been correctly cut at right angles, the 4 dies work in unison to cut

.gif) a perfect thread. (Fig. 2) a perfect thread. (Fig. 2)

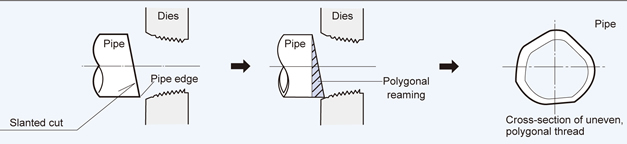

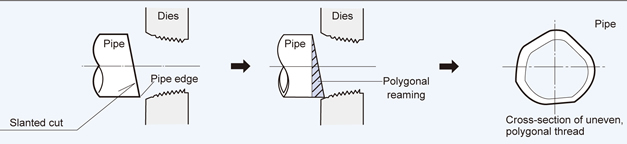

.gif) - When a thread is cut on a steel pipe where the end of the pipe is slanted or has steps, the result is a polygonal - When a thread is cut on a steel pipe where the end of the pipe is slanted or has steps, the result is a polygonal

.gif) thread or a pipe of uneven thickness. (Fig. 3) thread or a pipe of uneven thickness. (Fig. 3) |

| |

Fig. 1 Acceptable and unacceptable pipe ends

Fig. 2 Principle of cutting threads with a set of dies

Fig. 3 Principle of polygonal threads |

| |

|

Using the right oil means consistent finishes and increases the life of the dies

|

| |

1) Cutting oil comes in 3 types: for use with tap water pipes, general plumbing, and

.gif) stainless steel pipes. stainless steel pipes.

.gif) As shown in the table below, use the correct cutting oil according to the type of pipe. As shown in the table below, use the correct cutting oil according to the type of pipe.

.gif) (Table 2) (Table 2) |

| Note: Using cutting oil for stainless steel on steel pipes will result in imperfect threads and leakages. |

| |

| |

Steel pipes for tap water |

Stainless steel pipes |

General plumbing pipes |

| For tap water pipes 50W-R, N50W |

OK |

|

OK |

| For general plumbing 246-R, N246 |

|

|

OK |

| For stainless steel pipes

100SW-R |

|

OK |

|

Table 2. Appropriate cutting oil |

| |

2) Changing cutting oil, and causes of a reduction in oil performance |

.gif) If any of the following occurs, it means it is time to change the cutting oil. If any of the following occurs, it means it is time to change the cutting oil.

.gif) 1) If the oil becomes cloudy: This is the result of water getting mixed into the oil. 1) If the oil becomes cloudy: This is the result of water getting mixed into the oil.

.gif) If the cutting oil contains more than 20% water, the life of the dies will be drastically reduced. If the cutting oil contains more than 20% water, the life of the dies will be drastically reduced.

.gif) 2) If the oil turns black: When the amount of oil flowing from the die head is reduced, the surfaces where the pipe is cut 2) If the oil turns black: When the amount of oil flowing from the die head is reduced, the surfaces where the pipe is cut

.gif) get very hot and smoke is produced. This greatly reduces the performance of the oil. get very hot and smoke is produced. This greatly reduces the performance of the oil.

.gif) 3) If the oil becomes 'shiny': This means that microscopic colloidal sediment or metal powder has become mixed in 3) If the oil becomes 'shiny': This means that microscopic colloidal sediment or metal powder has become mixed in

.gif) with the oil. Change the oil. with the oil. Change the oil. |

| |

3) Amount of cutting oil |

.gif) The oil coming from the die head should flow continuously without interruption, and no smoke should be produced. The oil coming from the die head should flow continuously without interruption, and no smoke should be produced. |

| |

| |

|

Inspecting the Thread

|

| |

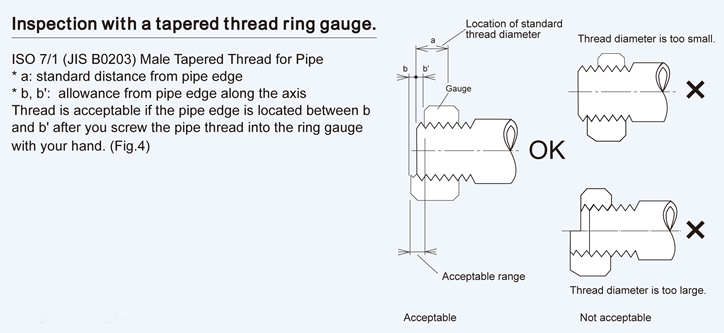

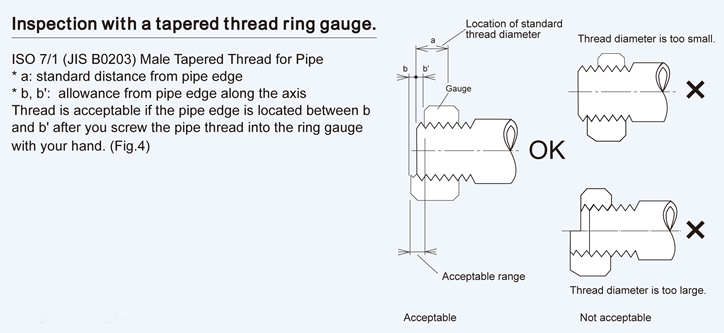

| - After making a thread, inspect it both visually and with a thread gauge to ensure it is accurate. |

| |

|

| |